February 4, 2025

Circularity in Action: the CommBank Stadium Success Story

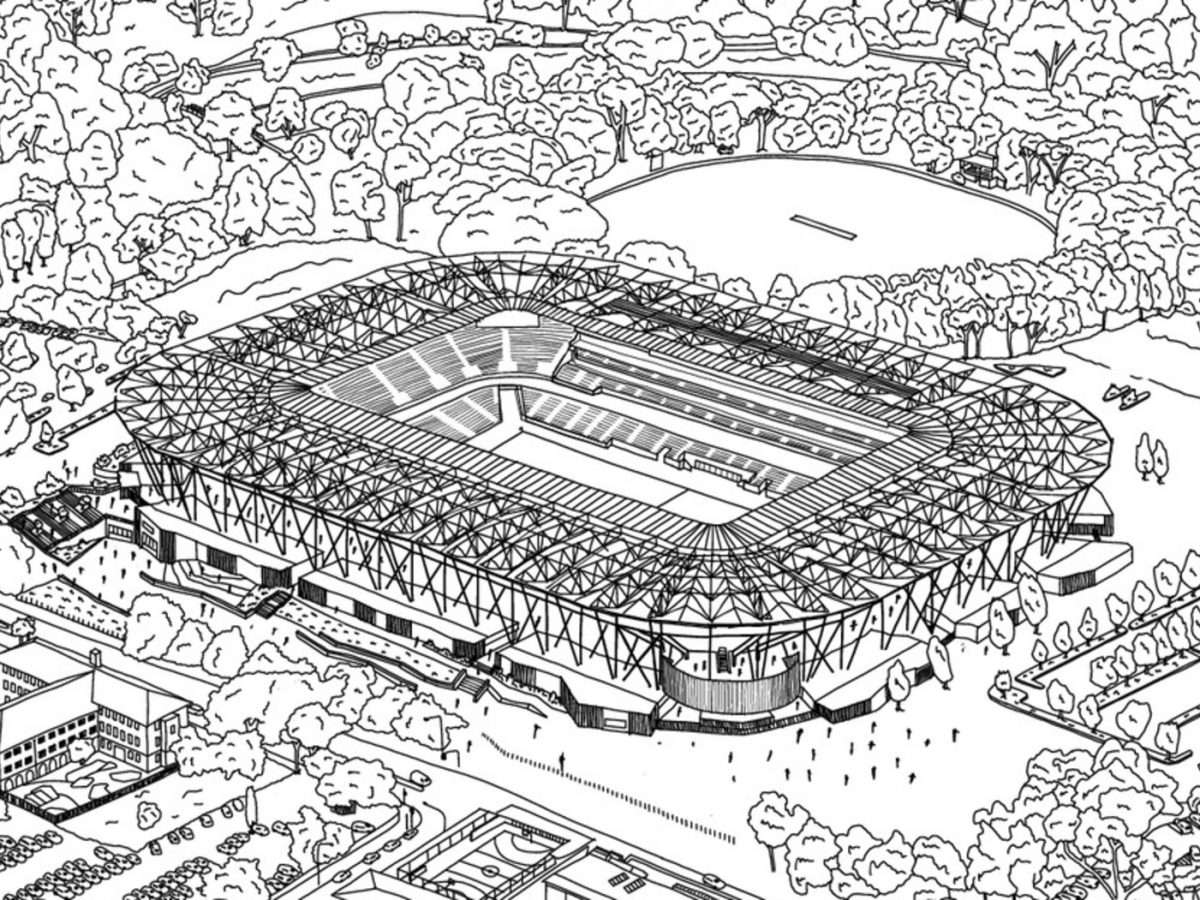

Delivered as part of the NSW Government’s State Stadia Strategy, CommBank Stadium is the first of two LEED v4 Gold stadiums in the Venues NSW network. The stadium caters to 30,000 spectators, provides an improved game-day experience and brings major economic benefits to the Western Sydney community. But at the core of the action is a story of circular stadium design.

Populous has committed to delivering net-zero buildings by 2030, and through our participation in the Building 4.0 CRC, an industry-led research initiative co-funded by the Australian Government, we are sharing lessons learned on CommBank Stadium, which was a case study in the #48 Shared Interest Project “Scoping Study for Building the Future – Circular Economy”. The project was led by Professor Leonie Barner from the Queensland University of Technology (QUT).

"Participating in the Building 4.0 CRC is not just about advancing knowledge; it’s about synergizing diverse expertise to push the boundaries of architecture and design to address the reality of the climate crisis."

The shared interest project provides a comprehensive roadmap for integrating circular economy (CE) principles into the Australian construction and building sector. A circular economy focuses on creating products, buildings, and public spaces that are durable and meaningful to users while minimizing resource use, waste, emissions, and energy loss through a system where materials are never waste and nature is regenerated. Given the complexity of the built environment, which consists of interconnected subsystems such as facades, mechanical systems and transportation, effective implementation requires collaboration among a diverse range of stakeholders.

CommBank Stadium is a key case study in this research project as it is one of a few examples of CE in the Australian stadium design context. This article looks at the circularity principles throughout the project based on the Building 4.0 CRC research interview conducted with CommBank Stadium project team members:

→ Client: NSW Government

→ Owner/Operator: Venues NSW

→ Project Delivery: Infrastructure NSW & Projects NSW in partnership with Venues NSW

→ Contractor: Lendlease

→ Architect: Populous

→ Engineer: Aurecon

→ Landscape architect: Aspect Studios

→ Steel manufacturer: BlueScope

About the project

CommBank Stadium is located in Parramatta, a major commercial centre in Greater Western Sydney, Australia. Designed by Populous as a 30,000–seat rectangular stadium, the CommBank Stadium is located next to Paramatta parklands, for sports, entertainment, cultural, community and business events. The design is an inspirational reflection of the manufacturing and industrial heritage of Parramatta with its exposed steel exterior and precast concrete concourse areas. Completed in April 2019, the project was a true collaboration between developer, architect, engineer, landscape designer and manufacturer.

"The stadium wasn't just seen as a venue—the project team knew that it would catalyse a vibrant new neighbourhood and become the heartbeat of the community."

Collaboration and efficiency

The project adopted a collaborative model, where developer, architects and engineers worked closely from the start. This is unusual on this scale of project but was necessary to facilitate circularity to ensure that every aspect of the lifecycle of the project was considered and worked seamlessly. This minimised costs and project timelines, and improved design accuracy. It also allowed the team to focus on the use of local suppliers.

Reusing materials from the existing stadium that was demolished, procuring off-the-shelf locally available materials, and designing for deconstruction, were central this collaborative approach.

The collaborative approach also ensured that representatives of the whole supply chain of building materials, such as BlueScope, were present during key design stages.

Designing for deconstruction

The stadium’s design follows a modular approach that facilitates disassembly. The design uses bolted steel instead of complex welding, making it more labour-efficient and suited for future reuse. All roof structural members were designed using a standardised uniform steel section, meaning less time and energy used to assemble and disassemble with all connections bolted. This means that all the steel can be reused for future projects if disassembled. Likewise, all precast concrete plats were bolted in place assisting in efficient future reuse. Use of standardised steel and concrete systems also decreased construction time.

This modular approach assisted with the transportation of materials to site as the stadium is located within a busy neighbourhood – less trips to site reduced the impact of construction on the wider community.

Material efficiency

In collaboration with Lendlease, local materials such as BlueScope steel welded beams were chosen, supporting the local economy and minimising transportation emissions. Precast concrete and modular steel designs were selected for efficiency and to reduce environmental impact.

Most materials, including steel, were selected for durability and reusability, adhering to CE practices. This was done by using bolted connections and junctions to avoid on-site welding and therefore reducing construction time. Recycled materials from the old stadium were reused in the new construction as foundation sub-grade, lowering the project’s environmental impact. This effectively reduced the use of ‘virgin’ materials in the stadium’s construction.

Another important design element was to use as little material as possible to reduce embodied carbon. For example, the northeast and south concourses do not have any cladding, which means no secondary steel building elements and cladding materials were used, enabling natural ventilation. Therefore, no mechanical ventilation system was needed, reducing both building and operation costs. Having no façade also enables natural lighting during the day.

Material consumption was also reduced by using a fabric for the roof. An advantage of fabric as a roof cover was the speed at which it could be installed. The fabric was installed beneath the steel frame rather than on the outside, creating the illusion of an elegant, floating fabric roof soffit that hides all horizontal structural elements from view and enhances the intensity and atmosphere of the seating bowl, adding to the overall viewing experience.

In addition, water is harvested from the roof fabric and used for irrigation, saving on town water supplies. All of these strategies and many more contributed to a 48% reduction in whole-of-life greenhouse gas emissions in comparison to the reference case, as per a LCA study conducted on the stadium.

"As an architect, I recognize the significant role the built environment plays in carbon emissions and ecosystem degradation. This presents an opportunity to view existing buildings as material repositories – a collection of reusable elements – and to embrace innovative design approaches that safeguard biodiversity."

Technological integration

Building Information Modelling (BIM) and 3D tools supported circularity by allowing the team to track and trace materials as well as plan for material reuse.

An additional layer of information such models provide is the ability to deconstruct a building and reconfigure it for its end-of-life use. You can hear Chris Paterson, Director – APAC at Populous, talk more about smart buildings, digital twins and the potential of mixed reality in the Inspiring Design podcast.

"CommBank Stadium is a material bank of the future—built to be circulated, not wasted. Its steel structure is designed for easy dismantling, ready for its next life. This circular vision was made possible by bold collaboration and a shared commitment to sustainability by the project team."

Future applications

The stadium design serves as a model for future circular civic infrastructure projects. Modular design using standardised components designed with the intent of deconstruction helps set a blueprint for creating a CE within the Australian construction industry.

Many of the insights from the project are helping build a roadmap for the CE in stadium design and construction. More on the Building 4.0 CRC CE roadmap.

CommBank stadium design team members included Richard Breslin, Senior Principal and Co-Managing Director APAC, Chris Paterson, Senior Principal, Director; Al Baxter, Senior Principal, Director; Shaun Gallagher, Senior Principal, Architect; Francine Conway | Populous, Associate, Architect; Andrew Wallace, Associate Principal, Architect; Nicholas Malyon, Associate Principal, Architect; and Nick Fitzgerald, Associate Principal, Senior Architectural Designer.

The Populous team engaging with Building 4.0 CRC included Dr Kavita Gonsalves, Associate Principal, Sustainability Design Lead – APAC, and Nick Fitzgerald, Associate Principal, Senior Architectural Designer.

You can learn more about CommBank Stadium and CE in the Think Future podcast.

Lorem ipsum dolor sit amet consectetur, adipisicing elit. Non facere corporis et expedita sit nam amet aut necessitatibus at dolore enim quis impedit eius libero, harum tempore laboriosam dolor cumque.

Lorem, ipsum dolor sit amet consectetur adipisicing elit. Illo temporibus vero veritatis eveniet, placeat dolorem sunt at provident tenetur omnis, dicta exercitationem. Expedita quod aspernatur molestias eum? Totam, incidunt quos.